The Purpose of Oil Refinery Plant

The crude oil getting from oil pressing or extraction plant certainly contain different amounts of non-oil impurities, such asmechanical impurities, free fatty acid, colloid, pigment, stink substances, moisture and wax, etc. These impurities will directly change the oil’s color, smell, taste, transparency, stability degree and nutrition, which not only affect the edible value, but also make the oil easy to deteriorate when storing.

The purpose of edible oil refining process is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality oil produces.

Provide the Best Solution of Edible Oil Refining

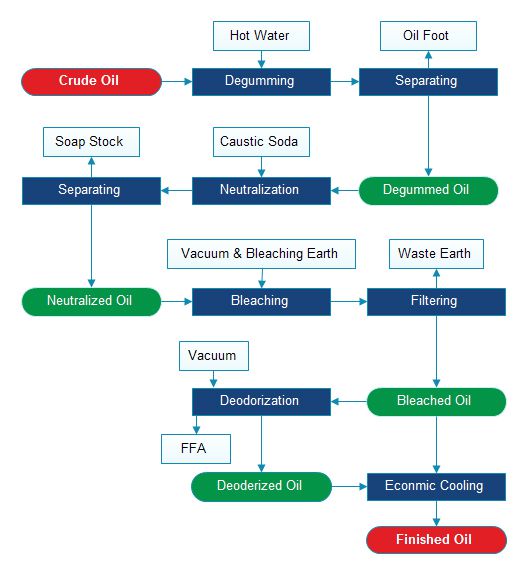

Referring to oil refining, the character of impurities contained in crude oil, and the purpose of refined oil must be concerned. ABC Machinery will customize the oil refinery process and solution for each of customer depending on their specific situation and needs.So called “refinery”, generally refers to deacidificationprocess. But in the broad sense, oil refinery process includes crude oil pretreatment, degumming, deacidifying, decoloring, deodorization, degreasing, and dewaxing process, etc. We will design the refining process depending on the quality requirements of refined oil.

For example, according to the relevant quality standard, edible oil refinery for soybean, peanut, and sesame, only needs pretreatment and degumming, and cottonseed oil refinery needs pretreatment, degumming and deacidifying, and rice bran oil refining needs pretreatment, degumming, deacidifying,decoloring, deodorization and dewaxing process to each the standard of cooking oil.

Complete Oil Refinery Plant

Capacity Range from 1T/D to 500T/D

Successful Projects of Oil Refinery Plant Build for Our Clients

1TPD Grapeseeds Oil Refinery Plant

1TPD Seal Oil Refinery Line

10TPD Paml Oil Refining Plant

10TPD Coconut Oil Refining Line

1TPD Sunflower Oil Refining

2TPD Canola Oil Refinery Equipment

5TPD Fish Oil Refinery

5TPD Sunflower Oil Refining

10TPD Oil Refining Equipment

Decoloration

Deodorization Workshop

Depickling Department

Oil and Fat Refining

Degumming Process

Degumming Process

Oil Refining Department

Decolorizing Section

Oil Refining Tank

Small Oil Refinery Line

Feel free to contact us through the below contact form to get more detqails of our oil material processing projects. Send us your requirements so we can offer you the tailor made soluations according to your situation. You will get a quick reply in one business day!

Choose the Most Suitable Refinery Methods for You

We will choose the refinery methods according to the different requirements of different types of oil. Both technical and economic effects are taken into account while plan the refinery plant, so that to build the best cooking oil refinery line which can remove the most completely unwanted and harmful impurity under the condition of minimum oil loss.Principles of Our Oil Refining Projects

Our vegetable oil refining projects are built based on the following principles:- In accordance with the general policy of economic construction in your country;

- Save energy;

- Ensure the quality of refined oil;

- Make full use of raw materials as far as possible, in an effort to achieve the maximize oil yield under thecondition of quality requirement;

- Comprehensive utilization of raw materials, finished products and by-products.

- Make the oil refining production mechanization and automation, improve the operating conditions and reduce labor intensity.

- Conforms to the safety operation specification

- Don’t bring environment pollution problem.

Edible oil refining is a complex process. To design a reasonable technological process, we also consider the following factors in addition to the above principles:

- Offer customized refining solution according to different oil varieties (soybean, peanut, cottonseed, rapeseed, vegetable seeds…).

- The application and qualification of refined oil. In addition to various levels of edible oil, there are base oil, drying oil, paint oil, pyrolysis oil, hydrogenated oil, salad oil, cooking oil, vegetable shortening and margarine, etc. Customized oil refining process will be offered to meet the quality requirements of different oil.

- Ensure the process of refining workshop is adapted to the production capacity of your enterprise. Continuous refining plant is suggested for production of large capacity, while batch or semi-continuous types aremore suitable for medium and small oil refining workshops.

- Others, such as the reliability of the equipment and technology,labor productivity, theconsumptionrate of auxiliary materials, steam, water and electricity.

- We are an agro product based company in India.We are interested to setup a small scale edible oil refinery. If your company has any office or dealer in India?

-

Thanks for your enquiry to our products. As for your request, could you kindly advise what's your raw material and desired processing capacity per day.

In you email, you mentioned that you want only refinery, do you know the index of the crude oil, such as moisture, acid value and peroxide value. We don't have office in India so far, all equipments is sold to your country directly to lower the product cost. -

I am from the Philippines, particularly in Mindanao island. I wan to know more about your company's small coconut oil refining line. We are assisting one group who is planning to establish small scale coconut oil refining plant to support their integrated business.

-

Could you kindly advise what's the capacity per day of the small coconut oil refining plant. So we could design and suggest for you accordingly.

By the way, is this group making crude coconut oil themselves or buy from outside...? Do you know the index of the crude coconut oil, such as moisture, acid value, peroxide value. etc. - I would like to get a quotation for types of sunflower oil extraction and refining machine. Thank you!

-

Tks for your enquiry to our products. As for your request, could you kindly advise what's your desried processing capacity per day..? so we could design and suggest for you accordingly. If possible, pls spare a little time to fill in the form in the email attachment. So we could know your demands clearly, thus give exact proposal for you soon

- I would like to get cost estimation for small scale coconut oil refinery line. Do you have any supplier in Sri Lanka?

-

As for your request, it's no problem to provide coconut oil refinery equipments to Sri Lanka.

The followings are some questions you need to consider first.

1. Do you produce the coconut oil yourself or buy from outside?

2. Do you have the index of the crude oil, eg, acid value, peroxide value, moisture..

3. Are you going to make RBD oil or VCO?

4. What's the cheapest fule for boiler at local, as the refinery system may need a furnance.

We'll desing and quote for you after getting your conifmation.

-

Dear Sir, Good day!

I am interested in the oil refinery processing machinery. Please advise ASAP. - Tks for your enquiry. Could you kindly advise what's your crude oil and what's your desired processing capacity of the refinery. Will design and suggest for you asap.

- We are very interesting plant refine vegetable oil. Capacity 20T per day. Crude oil.

-

Tks very much for your enquiry to our products. KMEC deals principally in designing, manufacturing and exporting complete oil mill plants, solvent extraction plants and related oil processing equipment. With more than two decades of experience, KMEC can ensure you get the best quatlity equipments and superior service.

As for 20TPD refinery, could you kindly advise the following questions

1. what kind of oil do you want to refine, peanut, soybean,sunflower?

2. where do you get the crude oil, make it yourself or buy from outside?

3. what's the index of the crude oil, eg, moisture, acid value, colour?

4. Which refining way do you prefer, batch type or semi-continouse?

5. Do you have boiler, what's the best economical fule in your country, coal, gas or diesel?

Build Your Future!

Build Your Future!