Start Sunflower Oil Business with Small Oil Expeller

All kinds of sunflower oil extraction machine for sale with lowest possible price and premium quality, supplied by ABC Machinery - one of the BEST oil machine manufacturers. With great reputaions in seed oil making field, we can offer the most suitable solution for both small and full scale vegetable oil producing business. You can trust both the machinery quality and after-services we offered.

Sunflower oil is extracted from sunflower seeds. It's a highly nutritious edible oil, rich in nutrients such as linoleic acid and vitamin E. It benefits the immune system, can prevent cancer, and due to its antioxidant and anti-inflammatory properties, it can also help prevent asthma. As a result, sunflower seed oil finds extensive commercial and household applications, especially in the food industry.

Why Choose Small Scale Sunflower Oil Making Machine?

In rural areas or households, people are increasingly focusing on how to make use of their harvests to produce sunflower oil. One solution is to utilize small-scale sunflower oil extraction machine. Let's explore the advantages of using small sunflower oil machines for home:

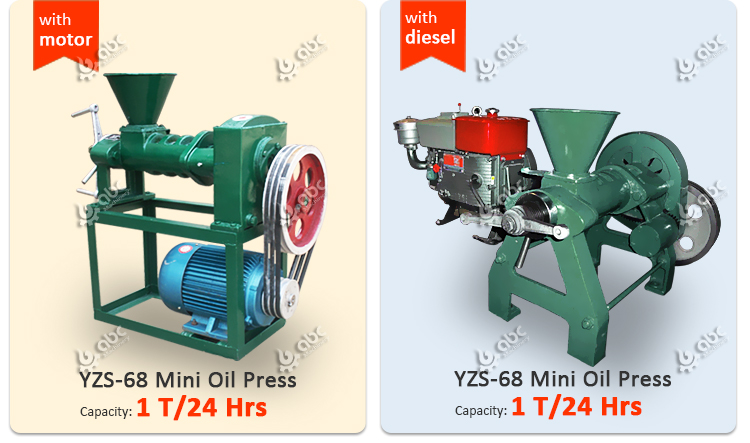

Sale Mini Oil Pressing Machine -- Different Powers

- Portability: Small sunflower oil machines are more light and easier to move and carry.

- Low Cost: Small oil making machine price are lower, so users can start sunflower oil business within their economic means, reducing investment risks.

- Ease of Operation: These machines are usually designed to be user-friendly, equipped with simple control panels and operation buttons.

- Energy Efficiency: Small scale sunflower oil expeller have lower power requirements, which can save energy and reduce costs.

- Fresh Sunflower Oil: Because it's extracted directly when needed, the time between sunflower and oil is short, which ensures freshness and quality of sunflower oil.

Screw Type Sunflower Oil Extraction Machine: Construction Principle

Next, we will delve into the core structure of small sunflower oil extraction machine, uncovering the functions and roles of its various parts. With this in-depth understanding, you will be able to grasp the essence of the small oil making machine more comprehensively, aiding the success of your business. Structural design of a small screw press typically includes several components:

- Feeding System: It is responsible for supplying the raw materials for processing in the oil press. It comprises a feeding hopper, feeding screw, and other components. The feeding hopper holds the raw materials, while the feeding screw pushes the raw materials from the hopper into the oil pressing chamber.

- Pressing System: It is the core part of the oil pressing machine and consists of the pressing screw and pressing chamber. The pressing screw is a screw-shaped metal rod with a design that gradually increases the pitch. The pressing chamber serves as the casing for the screw, where the screw rotates.

- Heating System: It is used to heat the oil pressing chamber as needed to improve the fluidity of the oil and enhance the extrusion process. This is typically achieved using electric heaters or steam heaters, allowing the temperature during the oil pressing process to reach an appropriate range.

- Control System: It monitors and controls the operational parameters of oil making machine, such as temperature, pressure, and speed. It ensures the stability and safety of the oil extraction process and optimizes the oil extraction efficiency by adjusting parameters.

Low-price Oil Pressing Machine for Sale

ABC Machinery has emerged as a renowned manufacturer and supplier of edible oil processing machinery. Our expertise and experience in this field have earned us a global reputation. We offer a wide range of products, including oil machines for home and commercial and refining equipment, capable of processing various oil-bearing seeds and nuts. For more information, please feel free to contact us at any time!

[Cost Analysis]Using Small Sunflower Oil Extraction Machines

Sunflower oil making machine price can be influenced by various factors, including machine size, quality, brand, and manufacturer. Here are some common price ranges for your reference:

- Low Range: These cheaper machines might be smaller in scale and lower in performance, but they can still be used for small-scale oil pressing operations.

- Mid-range: Price ranges usually fall between a few thousand dollars to around ten thousand dollars. These machinery generally offer good performance and durability, suitable for small and medium-scale oil making plant.

- High Range: Higher price range, usually exceeding ten thousand dollars. These machinery often come from well-known brands or professional manufacturers, featuring advanced technology and larger capacity, suitable for commercial oil pressing production.

In addition to the equipment purchase cost, you should also consider the following related costs(Related Post:Fully Automatic Mustard Oil Plant Cost>> ):

- Transportation Costs: Shipping the equipment from the manufacturer to your location might entail additional transportation costs.

- Installation Costs: Depending on the type and scale of the equipment, you might need to pay for installation to ensure proper setup and operation.

- After-sales Service and Maintenance Costs: Some manufacturers might offer after-sales service and equipment maintenance support, and you should assess the relevant costs based on the actual situation.

Cost Analysis of Producing 10TPD Sunflower Oil

| Costs | Amount(USD) |

|---|---|

| Land Costs | $30,800 |

| Factory Construction | $76,900 |

| Oil Production Equipment | $123,100 |

| Packaging Equipment | $15,400 |

| Raw Material Purchases | $230,800 |

| Labor Costs | $30,800 |

| Environmental and Safety Costs | $7,700 |

| Marketing and Sales Costs | $46,200 |

| Other Costs | $15,400 |

| Total | $576,200 |

(Note: this is just a example, and actual costs may vary due to various factors. Before making any actual investments, it is important for you to conduct detailed market research and budget planning to obtain a more accurate cost analysis.)

Production Process of Small Sunflower Oil Factory

Sunflower oil production processes generally include both pressing and solvent extraction methods. In this article, we mainly focus on starting a sunflower oil business using a small screw oil press, so we will primarily discuss the sunflower oil pressing method.

Pressing method involves using external force to squeeze the oil out of sunflower seeds without the use of other solvents. Sunflower oil pressing process retains various beneficial nutritional components in the oil, such as polyunsaturated fatty acids, proteins and vitamins,which are beneficial for human health.

Mimi Oil Mill Plant Setup

Small(10TPD) Sunflower Oil Production Line in Uganda

Mini Oil Mill Plant : a cleaning sieve, cooking machine, integrated oil press, and screw elevator. Compared to large-scale automated oil mills, it requires less space and investment, while still encompassing full functionality of an oil mill. This mini oil press plant requires less labor than a single oil press, only two or three workers for the entire plant.

Small Edible Oil Production Line : dehuller, cleaning sieve, roasting machine, screw oil press, filtering machine, refining equipment, enabling higher production capacity and a comprehensive production process.

Here's a reference for you: construction cost of a 5-ton/day oil mill is approximately $7,500.(Read More: Sunflower Seeds Processing Machine>>)

If you are planning for starting your sunflower oil business and need a complete plant plan, ABC Machinery will be your BEST choice! Feel free to contact us for detailed information and latest price. We are always glad to service you!

Build Your Future!

Build Your Future!